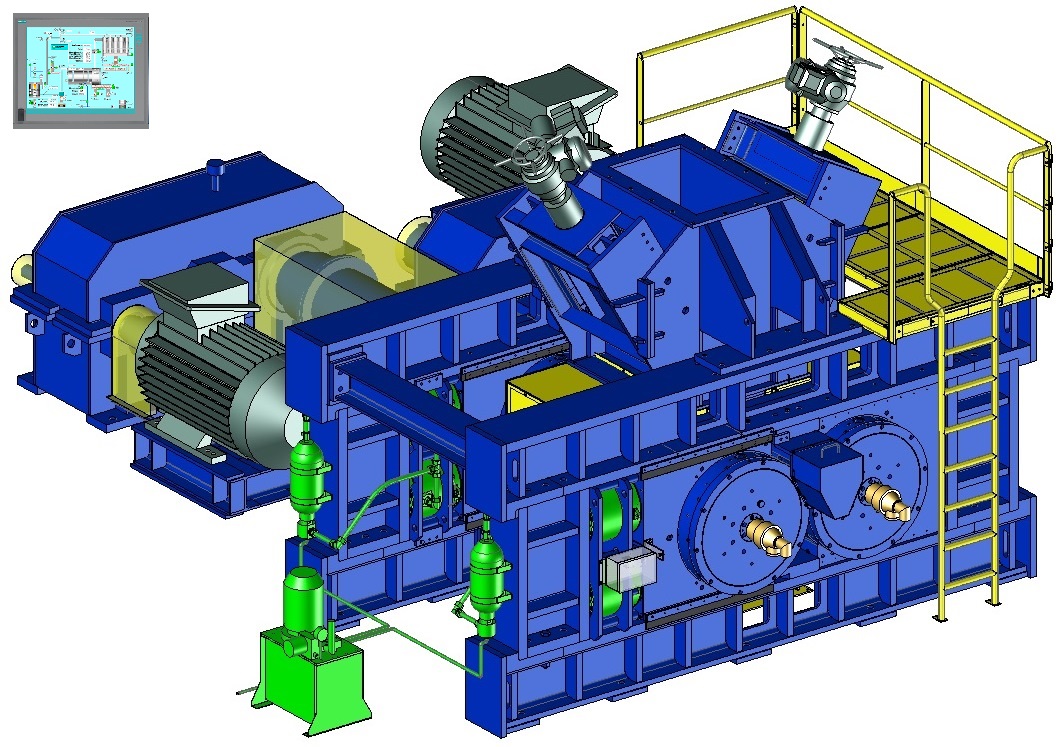

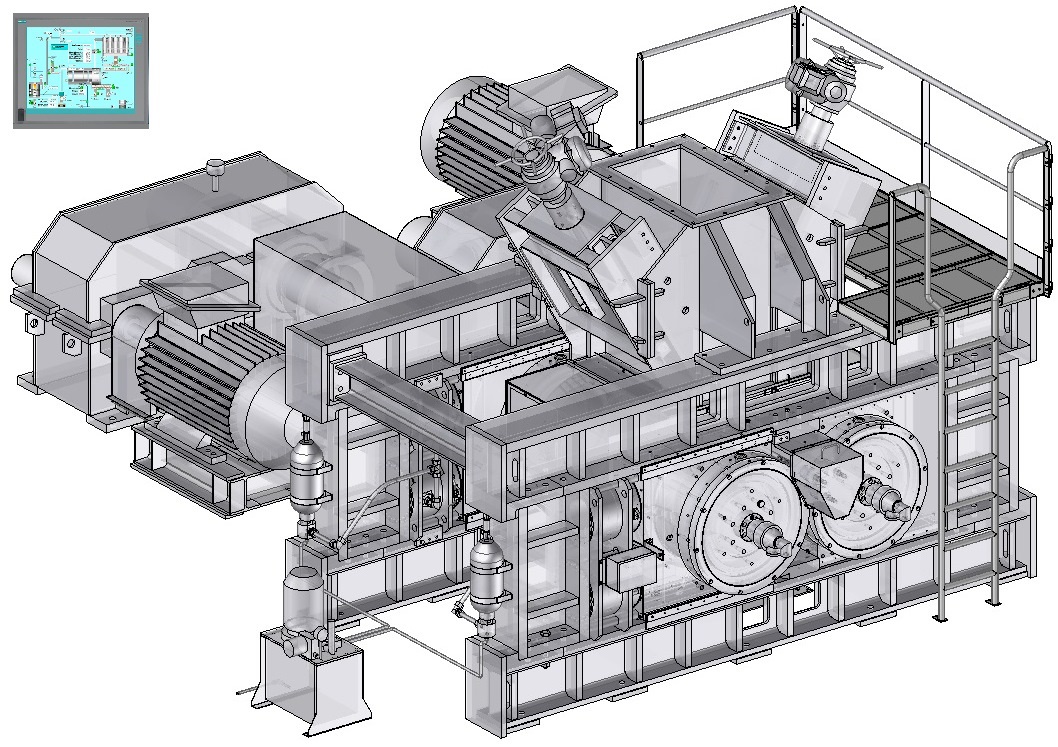

Roller press

SAHUT‐CONREUR

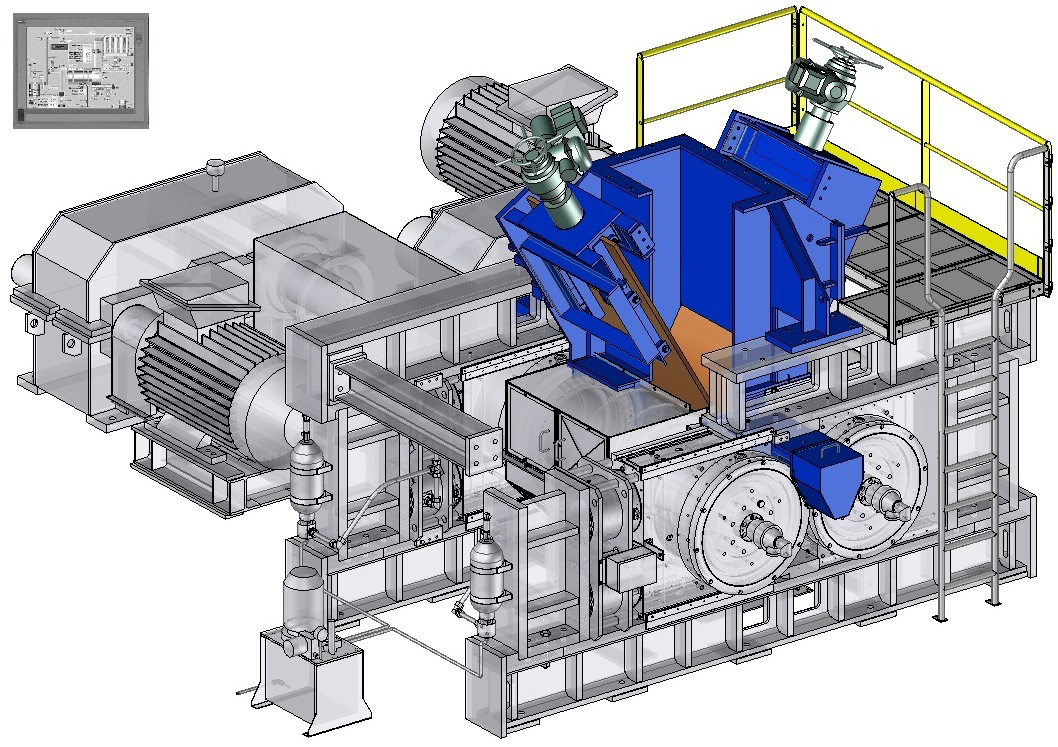

designs and manufactures roller presses for heavy-duty operation under hard and difficult conditions, with reliable use and minimal maintenance.Click on the different part of this roller press for discover its main components.

Dynamic view

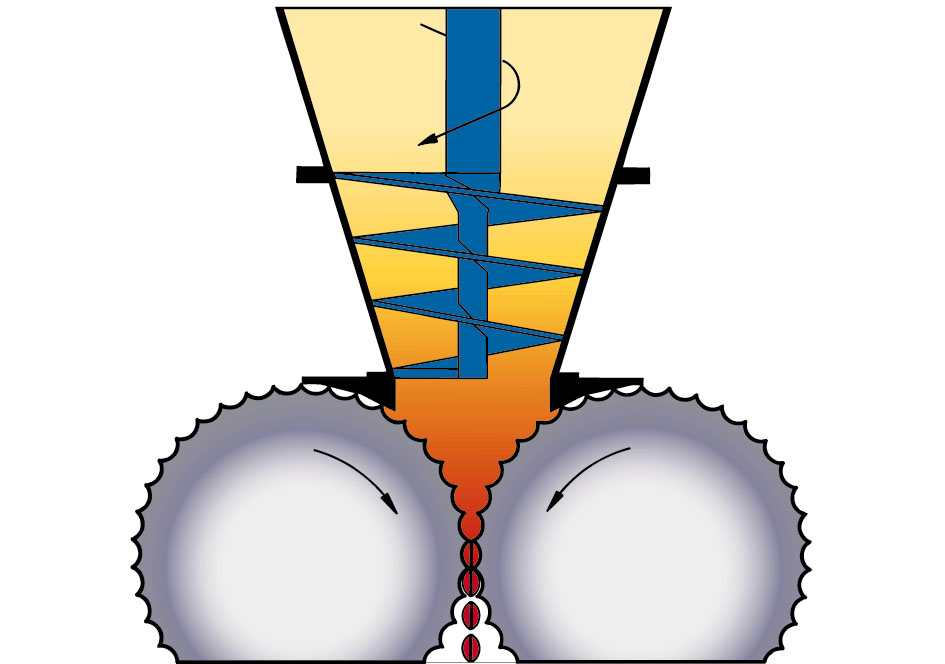

Feeding system

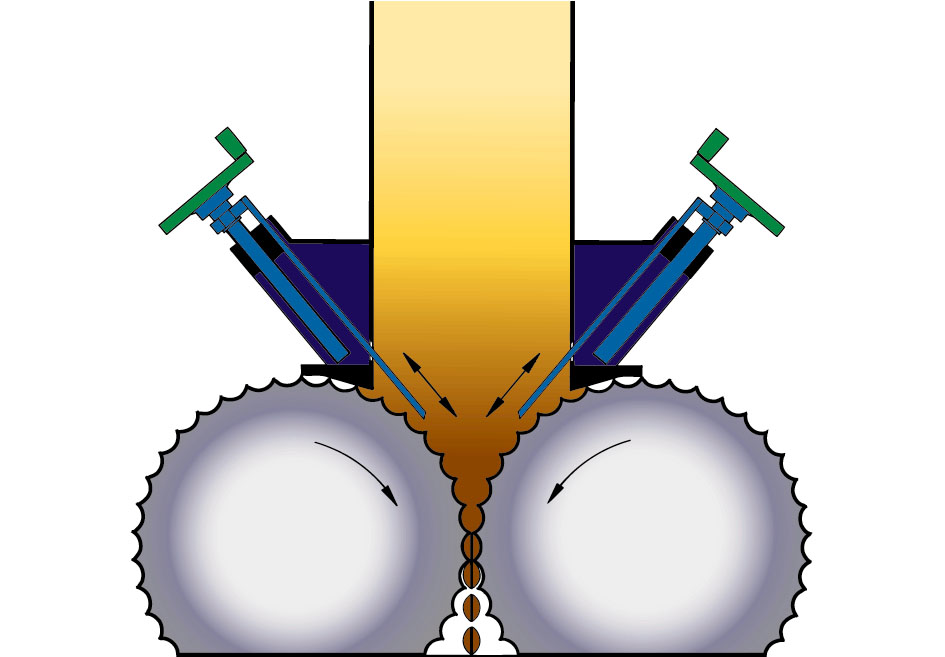

Usually the roller press is fitted with a hopper with inclined flaps. However, for a large scale of output, low density and low flowing products, a force-feeder with a predensification screw can replace the hopper with flaps.

The hopper

Feeding the rollers by gravity, this system can, if necessary, be fitted with inclined flaps whose the position is manually or automatically adjusted.

The force-feeder

Predensifying the product and feeding the rollers.

These 2 feed systems can be equipped with special floating cheek plates system reducing the

powder leakage on the rollers sides and providing a better efficiency in the grinding area.

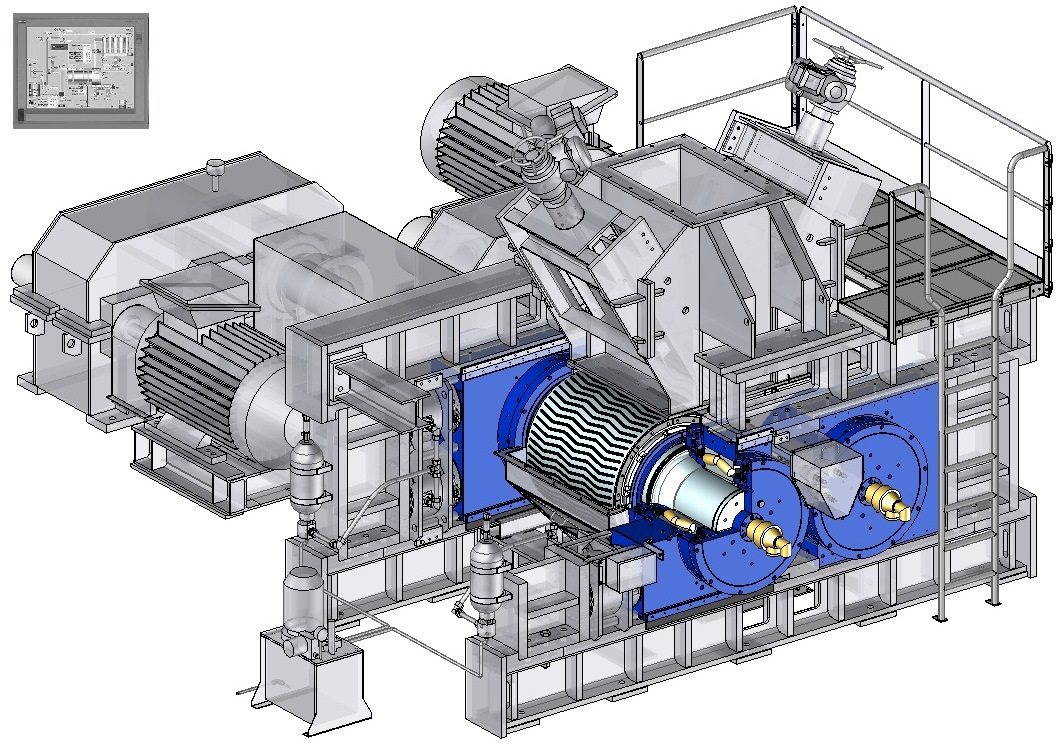

Rollers

Rollers surface

The roller press is composed of two rollers : One is fixed in the roller press frame whereas the other one can move perpendicularly to its axis varying the space between them. The size of the Roller Press is characterised by the roll diameter (from 400 to 1600 mm) and the roll width (from 100 to 1000 mm).

Usually forged steel tyres with resistant material and hardening treatment are installed on the

rollers offering a long operation life. For specific application end products, forged steel monobloc

rolls with an abrasion resistant working surface (deposit of a baselayer and chevron or straight

seams) can be installed but other technological solutions such as segments can be implemented

according to the abrasiveness of the feed material.

Rollers bearing

These rollers are mounted on heavy-duty bearings sized for a long life-time, manually or automatically lubricated by grease or oil. For particular applications, the cooling of shafts and bearings can be installed.Frame

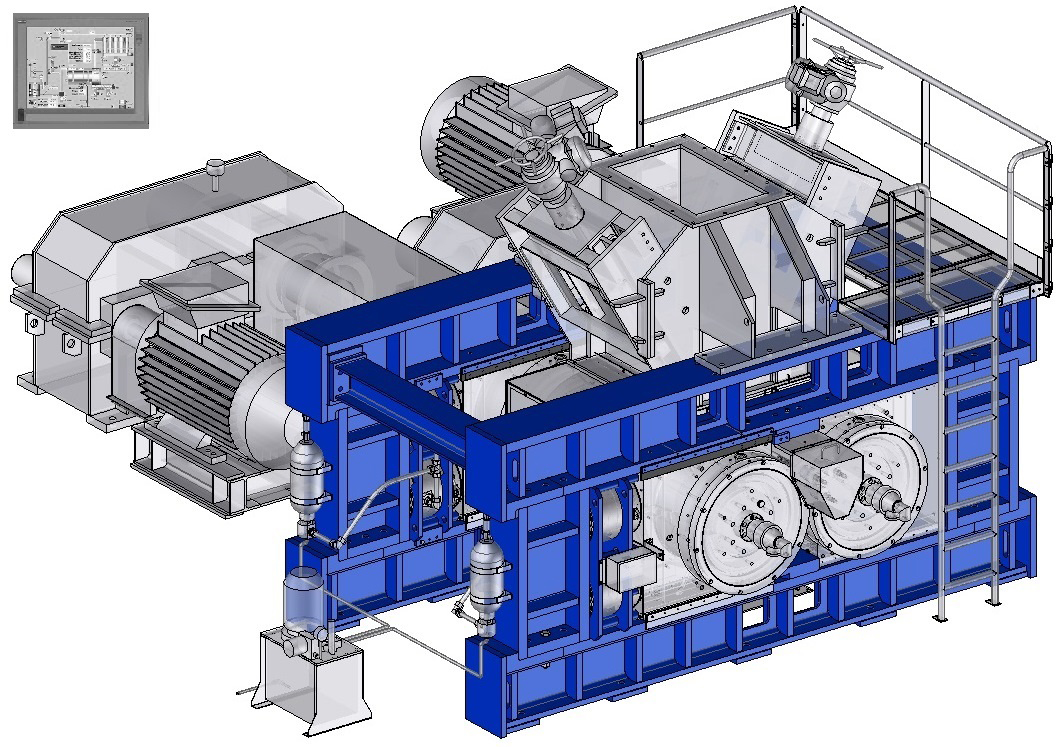

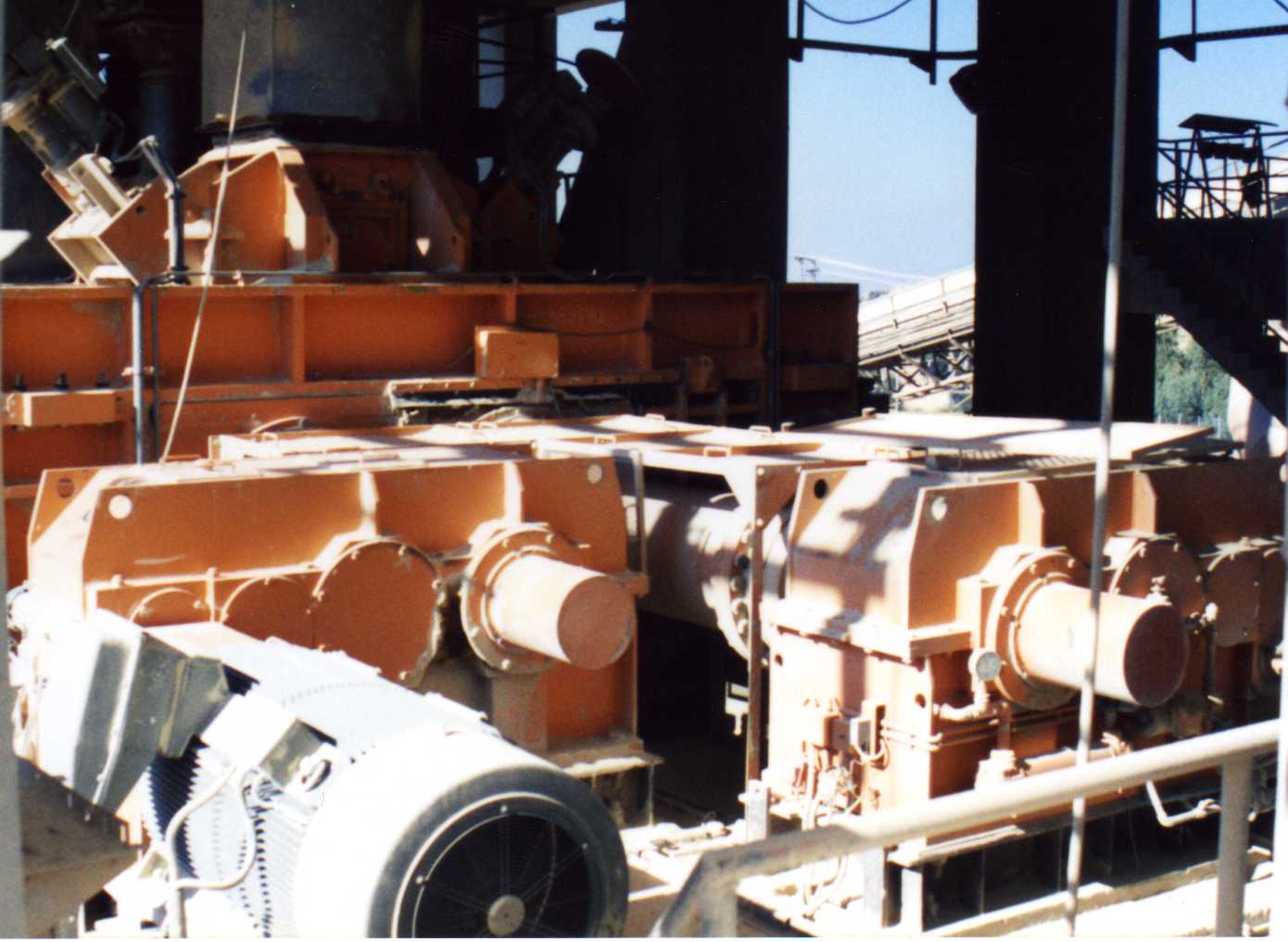

The roller press is composed of a special steel frame machined and assembled with a sufficient mass for heavy-duty operation under high pressure.

Hydraulic System

The roller press is equipped with an hydraulic system able to apply a force on the mobile roll by means of jacks. This force can be different in certain cases on each bearing block of the mobile roll thanks to a double hydraulic circuit. This system also includes safety devices and nitrogen accumulators to dampen the movement and quick return of the mobile roll and protect the Roller Press when tramp material is inadvertently fed to the rolls.

The force applied on the product can vary from 10 to 120 kN/Lcm (Linear centimeter of roller width) wich is equivalent to approx. 2-10 N/mm².

Rollers drive

Usually a special two outputs gear-box installed to drive the rollers. When high-power presses is required for the application, each roller is driven by a one output gear-box fitted with internal gear couplings which can withstand misalignement. In particular cases (high torque, restricted space, …) other drive systems (planetary gear-box, hydraulic motor) can be used. The roll speed can go up to 25 Rpm and even higher in particular cases; it corresponds to a tangential roll speed up to around 0,8 m/s.The rollers drive is designed for heavy, high and alternating impact loads during grinding.

Control-automation

A high automation level ensures constant continuous operation of the roller press without operator. The control-drive system is based on signals from the measurement of the rollers gap, the grinding pressure value and the power absorbed by the rollers drive.

In case of hopper with flaps installed as feed system, two means of control can be installed on the roller press:

In case of hopper with flaps installed as feed system, two means of control can be installed on the roller press:

- Either control of power consumed by the rolls drive by positioning of the feed flaps.

- Or control of rolls gap by positioning of the feed flaps.

- Either control of power consumed by the rollers drive by adjusting the speed of the screw shaft.

- Or control of roller gap by adjusting the speed of the screw shaft.