Mixing equipment

Thanks to its long and fruitful experience acquired in the briquetting fields since more than 160

years,

SAHUT-CONREUR

has developed its own range of mixers. Considering the large variety of products to be processed and the binders used, the range of mixers designed and proposed by SAHUT-CONREUR is specifically adapted to each type of briquetting.Pugmill

SAHUT-CONREUR

has developed its own range of (steam) pugmills. These pugmills are specially adapted for the application of coal, lignite, charcoal and coke where the binders used are tar pitch or liquid bitumen or starch combined with steam injection or a combination of quicklime and molasses. Over the last 100 years, many of our pugmills are running in heavy- duty operation under hard and difficult conditions. Our pugmills cover a large capacity range from 3 T/hr up to 100 T/hr.- Adjustable mixing time

- Steam injection at the heart of the mixture for a very high homogeneity

- No product damage

- Solid and liquid additive

- Heavy duty design

- Safe and fully accessible

- Low maintenance

- Power consumption adapted to application

Options

Our vertical mixers can be customized following the below options:- Stainless steel 304L / 316L material construction

- Thermal insulation / temperature jacket

- Trough in special anti-wear material

- Special tools arrangement for specific application

- Solid / Liquid injections

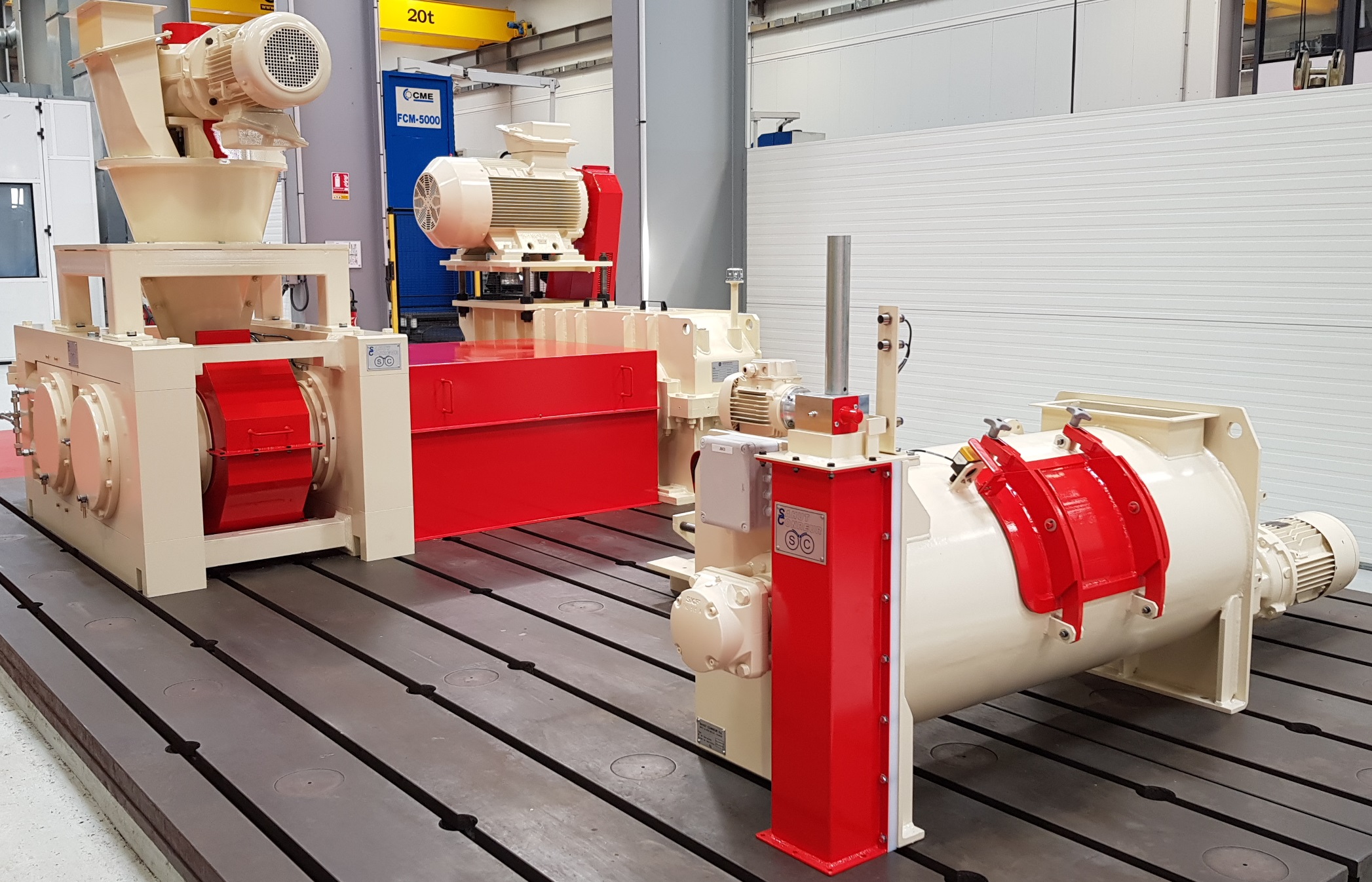

Twin screw mixers

SAHUT-CONREUR

has developed its own range of twin screw mixers specially adapted for spraying water or liquid agent. These twin screw mixers are implanted in steel-making, chemicals and minerals plants for heavy-duty operation under hard and difficult conditions. Our twin screw mixers cover a large capacity range from 500 Kg/hr up to 50 T/hr.- Adjustable mixing time

- No product damage

- Solid and liquid additive

- Heavy duty design

- Safe and fully accessible

- Low maintenance

- Power consumption adapted to application

Options

Our twin screw mixers can be customized following the below options:- Stainless steel 304L / 316L material construction

- Thermal insulation / temperature jacket

- Trough in special anti-wear material

- Special tools arrangement for specific application

- Solid / Liquid injections

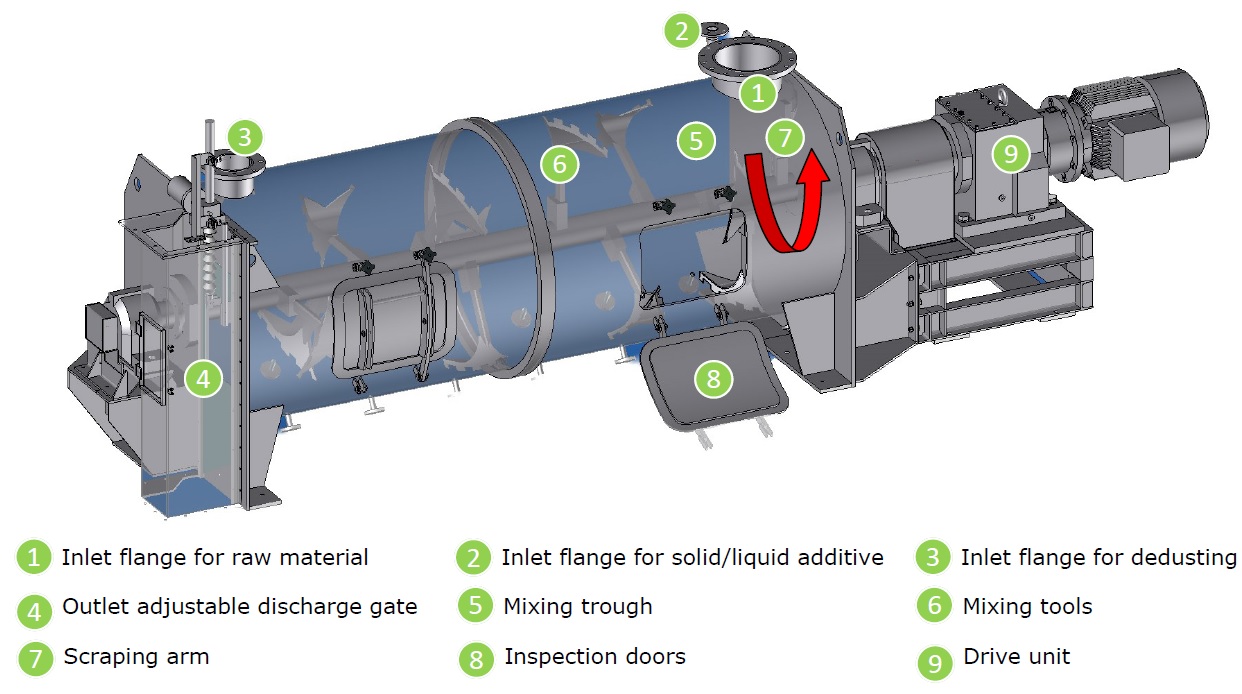

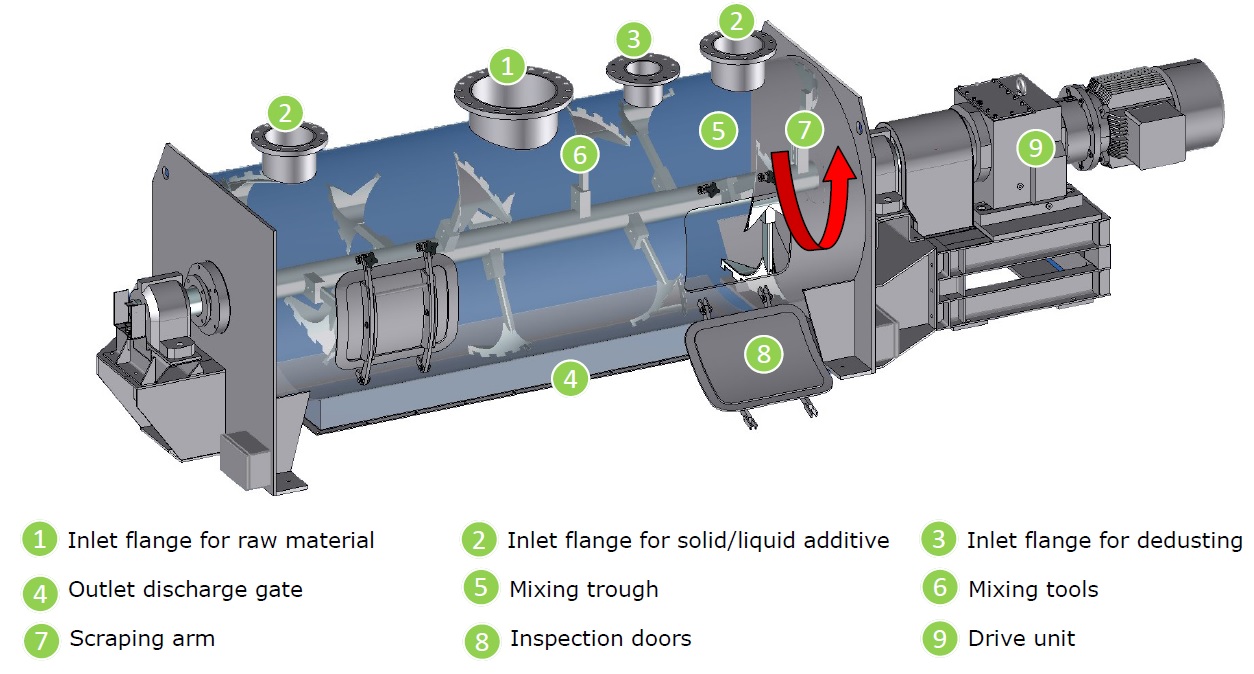

PLOUGHSHARE MIXER

SAHUT-CONREUR

has developed its own range of intensive continuous and discontinuous (batching) ploughshare mixers. These ploughshare mixers are specially adapted for the application requesting an high quality mixing in a very short time. Over the last 30 years, many of our ploughshares mixers have been implanted in steel-making, chemicals and minerals plants for heavy-duty operation under hard and difficult conditions. Our ploughshare mixers cover a large capacity range from 500 kg/hr up to 100 T/hr.

- High mixing efficiency

- Adjustable mixing time

- No product damage

- Solid and liquid additive

- Heavy duty design

- Safe and fully accessible

- Low maintenance

- Power consumption adapted to application

Intensive continuous ploughshare mixer MSC type

Continuous ploughshare mixer type MSC 6000

Continuous ploughshare mixer type MSC 4200

Continuous ploughshare mixer type MSC 340

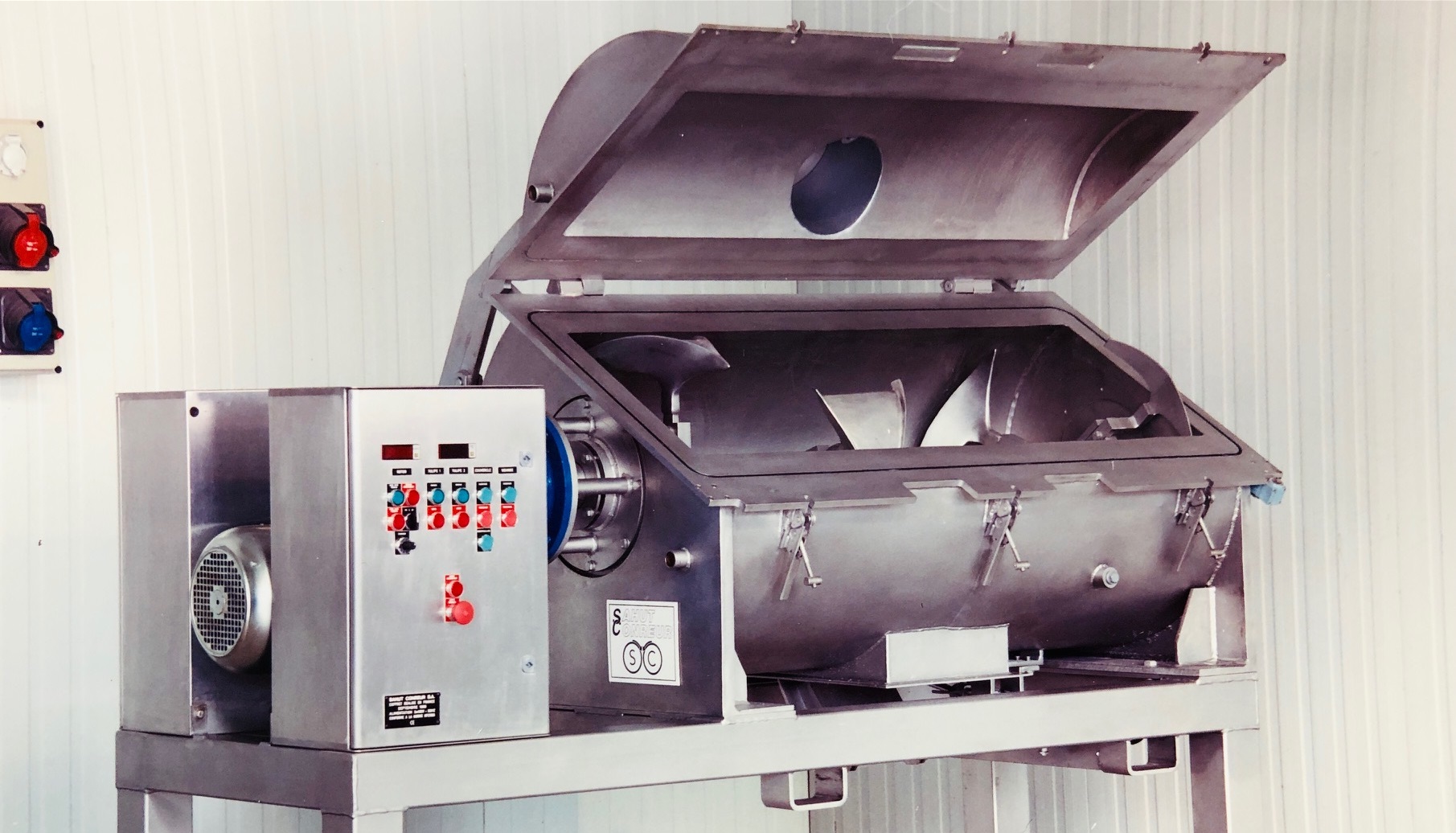

Intensive discontinuous ploughshare mixer MSD type

Discontinuous ploughshare mixer type MSD 3000

Discontinuous ploughshare mixer type MSD 340

Discontinuous ploughshare mixer type MSD 340

Mixing tools

Our intensive ploughshare mixers can be equipped with the below mixing tools:

Standard plough

Overlayed plough

Toothed plough

Blade plough

Options

Our intensive ploughshare mixers can be customized following the below options:- Stainless steel 304L / 316L material construction

- Thermal insulation / temperature jacket

- Trough in special anti-wear material

- Chamber fitted with replaceable wear parts

- Chamber fitted with special anti-sticky rubber coating

- Special tools arrangement for specific application

- Solid / Liquid injections

Continuous ploughshare mixer type MSC 340

Continuous ploughshare mixer type MSC 340

High speed mixers

SAHUT-CONREUR

has developed its own range of high speed mixers specially adapted for spraying water or liquid agent. These high speed mixers are implanted in chemicals and minerals plants for continuous operation. Our high speed mixers cover a large capacity range from 50 Kg/hr up to 5 T/hr.- No product damage

- Solid and liquid additive

- Heavy duty design

- Safe and fully accessible

- Low maintenance

- Power consumption adapted to application

Options

Our high speed mixer can be customized following the below options:- Stainless steel 304L / 316L material construction

- Thermal insulation / temperature jacket

- Special tools arrangement for specific application

- Solid / Liquid injections