Compaction: why ?

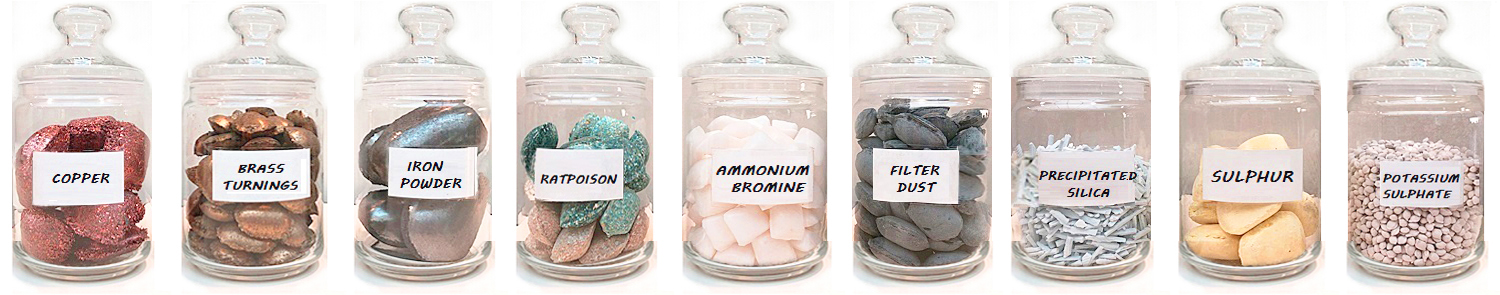

Briquetting (agglomerates, briquettes, compacts, ... ), and compaction-granulation (granules) processes are technologies of particle size enlargment using a dry process in which dusts or powders are formed into calibrated shapes.

A Technical Solution

- Obtain products of the same size, volume and weight: an agglomerate/a compact can represent the exact dose required in a process.

- Obtain a specified and constant product size-range.

- Reduce the volume of a powder.

- Stabilize mixtures of powders: during handling and transport, the heterogeneous mixtures of particles lose their uniformity because of the variation in density, shape and size of the particles. The problems of segregation disappear.

- Improve the flowability of the powders, thus preventing problems of feed, dosage or packaging.

- Improve the compactability of some powders.

- Eliminate the problems of dust generation during handling.

- Control the hardness and strength of products.

- Control the dispersion rate of granules.

- Solve the problems of powder caking during storage.

A Commercial/Marketing solution

- Increase the sales appeal of a product.

- Facilitate dosage use: a briquette can represent the exact dose required in a process for ease of exact dosage.

An Environmental solution

- Recycle industrial waste.

- Recycle beneficiated dust in an industrial process.

- Eliminate pollution problems caused by airborne dust : air and ground pollution.

An Economical solution

- Replace the wet process of agglomeration involving costly drying and binder addition techniques.

- Allow more flexibility in the choice of raw materials purchased at the most attractive price (Fertilizer compounds).

- Adapt easily and quickly to a wider range of mixed fertilizer formulas.

- Granule products that cannot be granulated by means of other techniques (wet process).

- Upgrade by-products.

- Reduce the packing, storage and transport costs thanks to a volume reduction and higher density of the product.

- Avoid loss of product in dust form.