Compaction-Granulation process

Compaction-granulation is a dry process that transforms powders into randomly shaped granules in a calibrated range (e.g. 0.2 to 0.8 mm, 0.4 to 1.2 mm, 2 to 4 mm, etc....). Usually no binder is required in this process and the bonding of the particles is only ensured by the mechanical pressure applied to the product to be compacted. The raw material is compacted, at low, medium or high pressure (depending on the properties of the raw material), in the form of flakes of variable thickness (up to 30 mm).

The capacity of a compaction-granulation unit can range from 50 kg/h to 50 T/h of granules and for products with a temperature up to 200°C, and over.

The capacity of a compaction-granulation unit can range from 50 kg/h to 50 T/h of granules and for products with a temperature up to 200°C, and over.

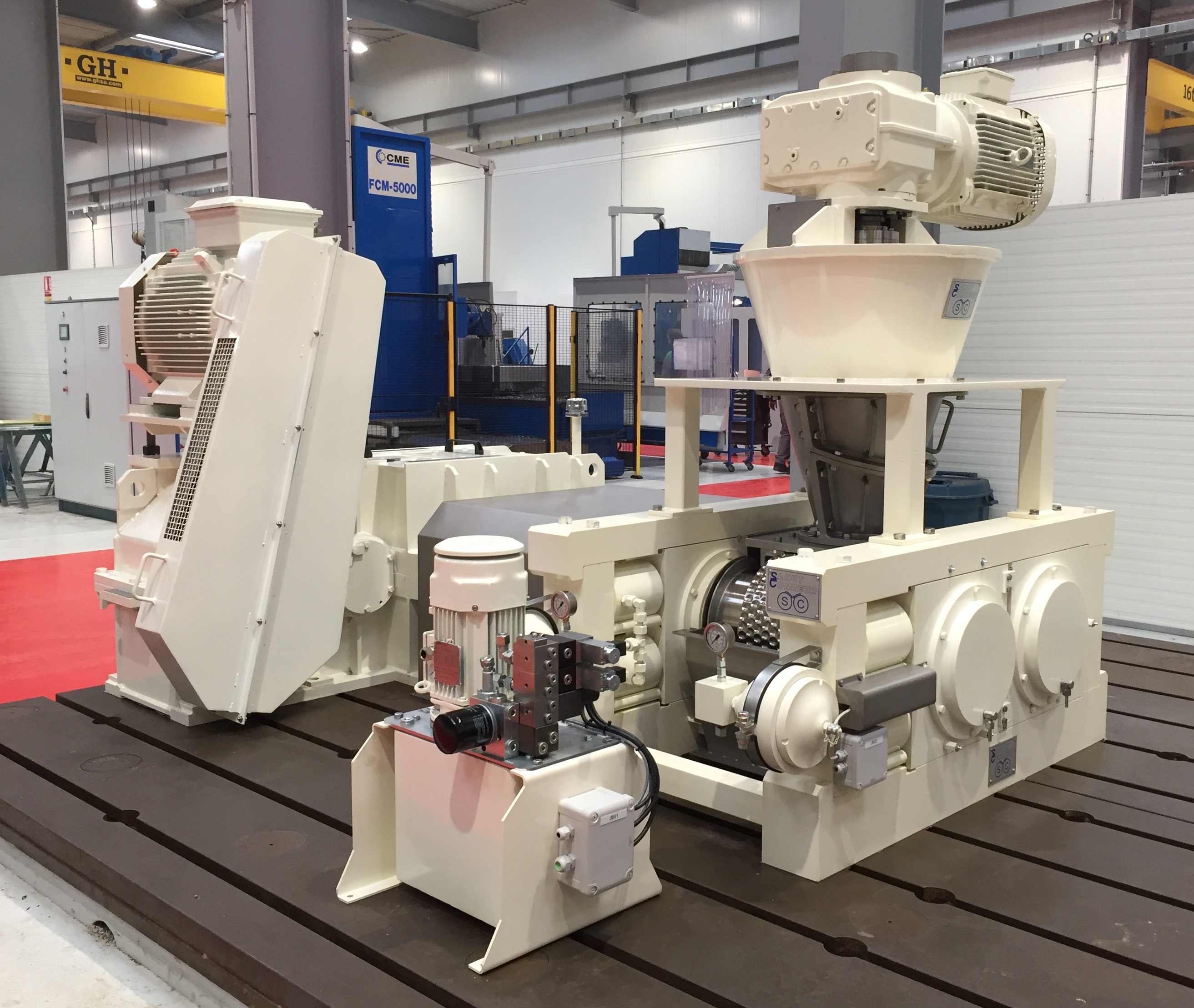

1 Tph antioxidant compaction-granulation unit

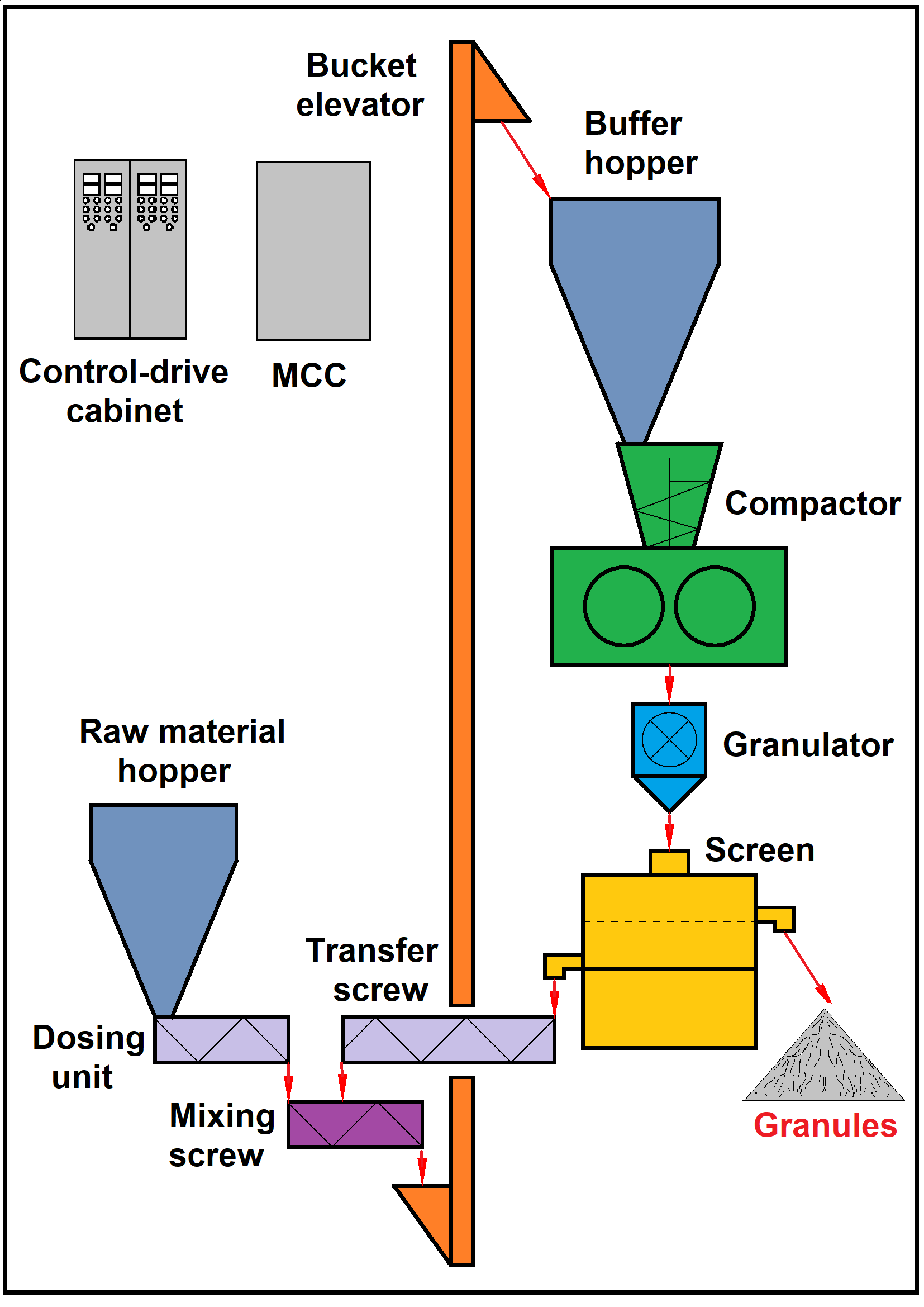

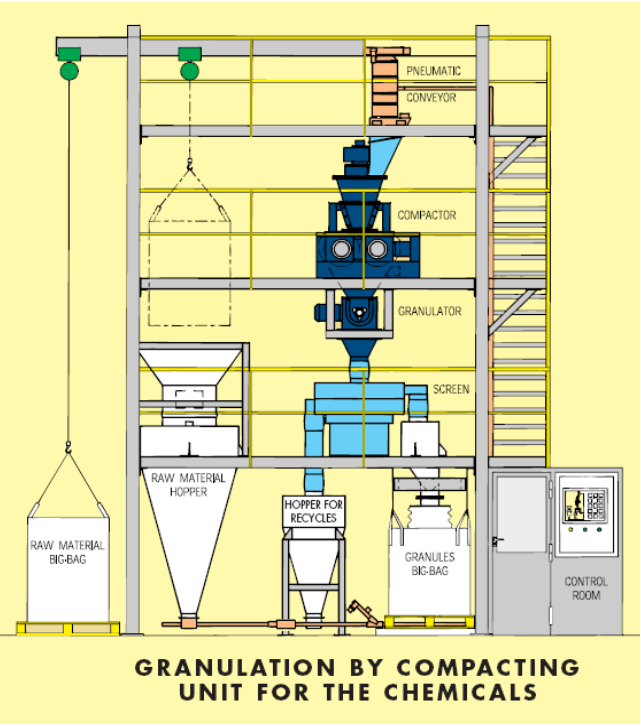

Usually, the main stages of the compaction-granulation process are as follows:

- (If necessary a preparation unit for raw material if necessary such as screening, crushing, drying.)

- A compaction unit transforming the powders into flakes.

- A granulation-screening unit converting the flakes into granules of the required calibrated range. The granulation process can be performed in one or two steps. With two steps the efficiency/yield of the complete compaction-granulation unit is improved.

Usual basic compaction-granulation plant using only granulation step

350-400 Kg/h glass powder compaction-granulation unit

A large range of equipment

HP1/400/100

HP1/600/300

HP1/800/300

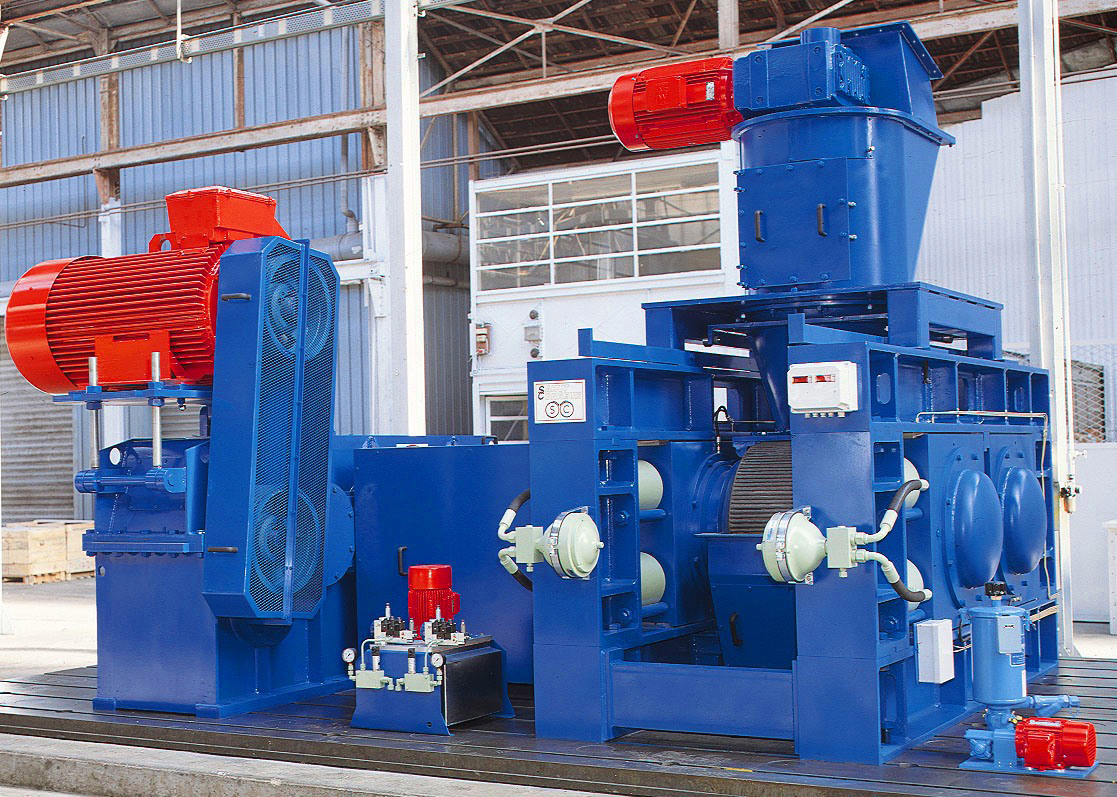

3 lines with HP1/800/360

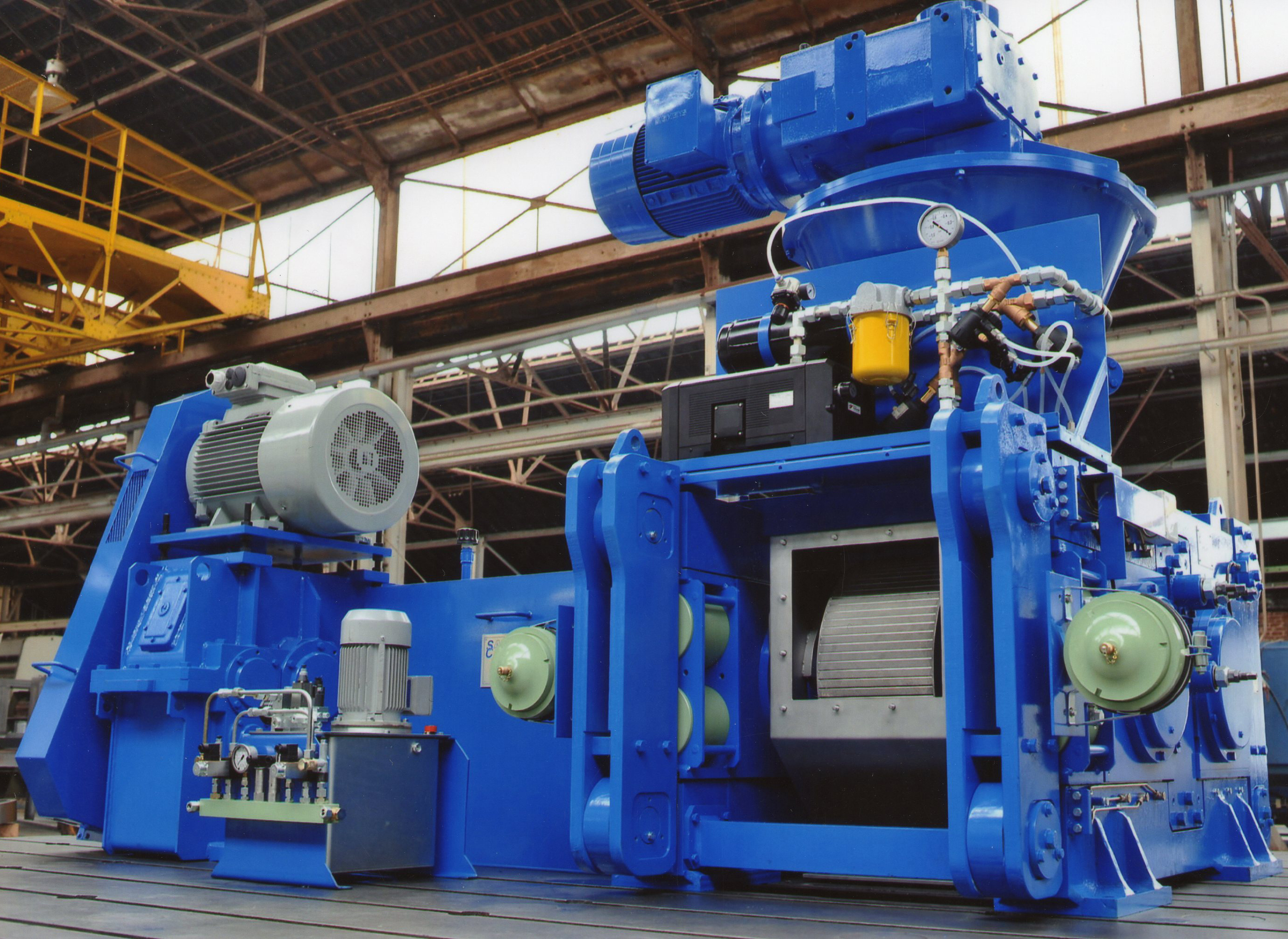

2 lines with HP2/1000/800

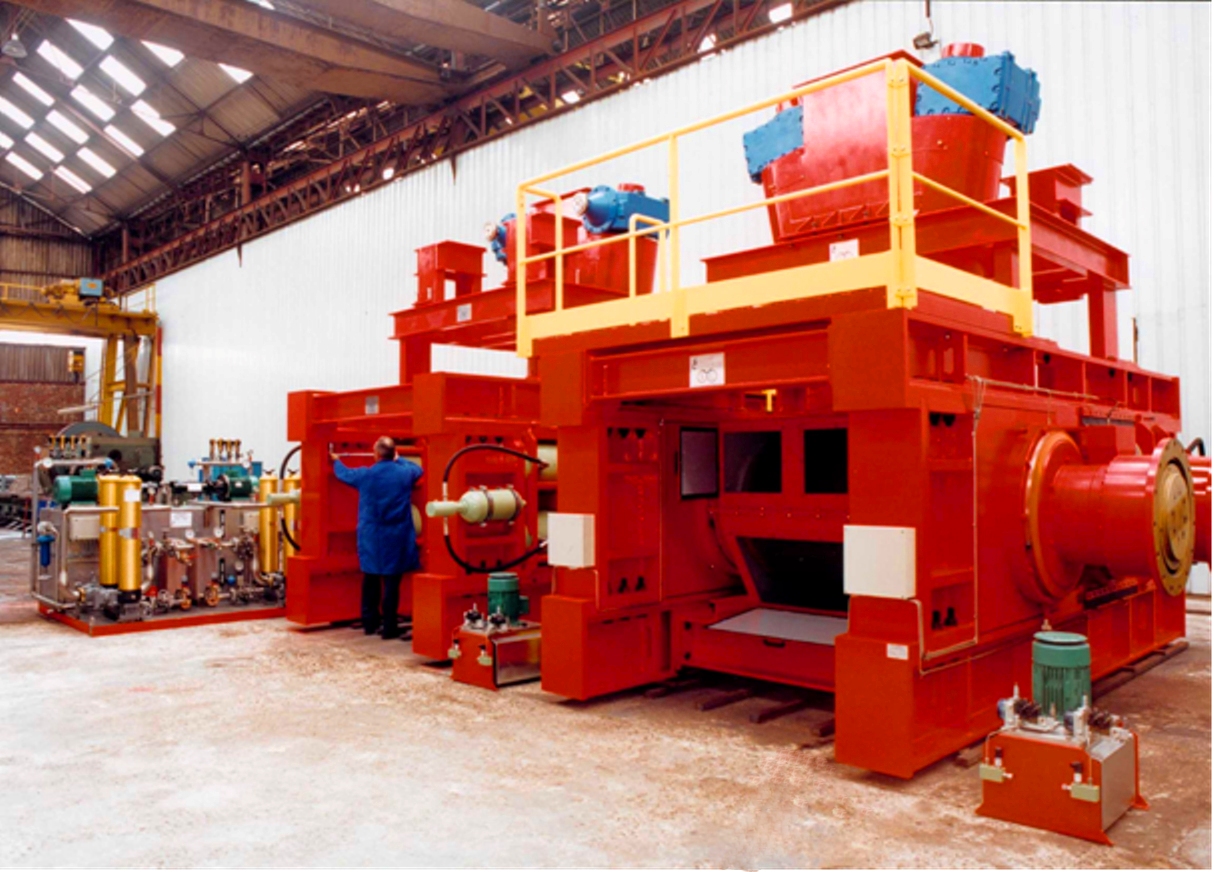

HP2/1000/1000

6 lines with HP2/1050/1000

4 lines with HP2/1200/1000