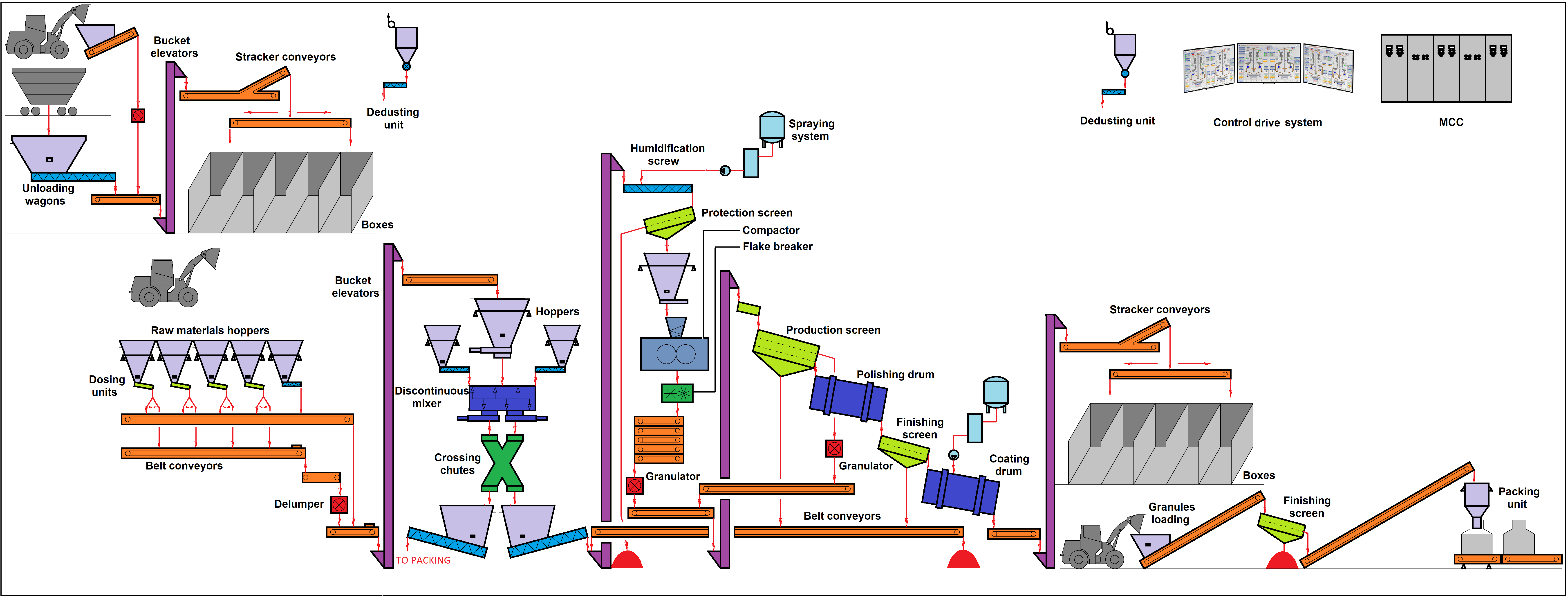

NPK compaction granulation

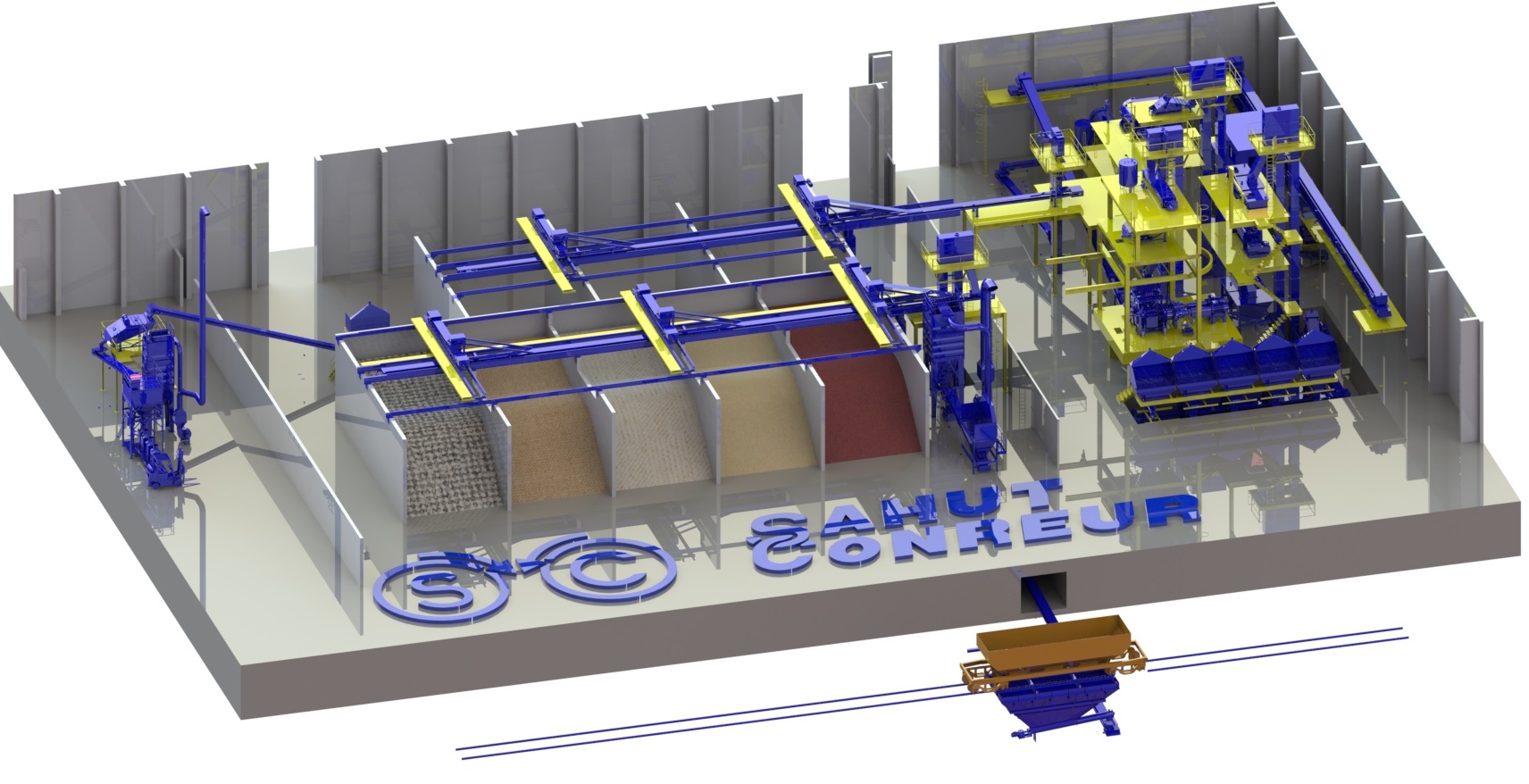

For fertilizers components (AS, KCI) and (NP, NK, PK, NPK) fertilizers, the main stages of the

process can be as follows:

- Unloading of raw materials from wagons or trucks and transferring into storage boxes.

- A preparation unit for raw materials (delumping, screening, crushing, drying).

- A weighing and mixing unit of the raw materials.

- A compaction unit transforming the powders into flakes.

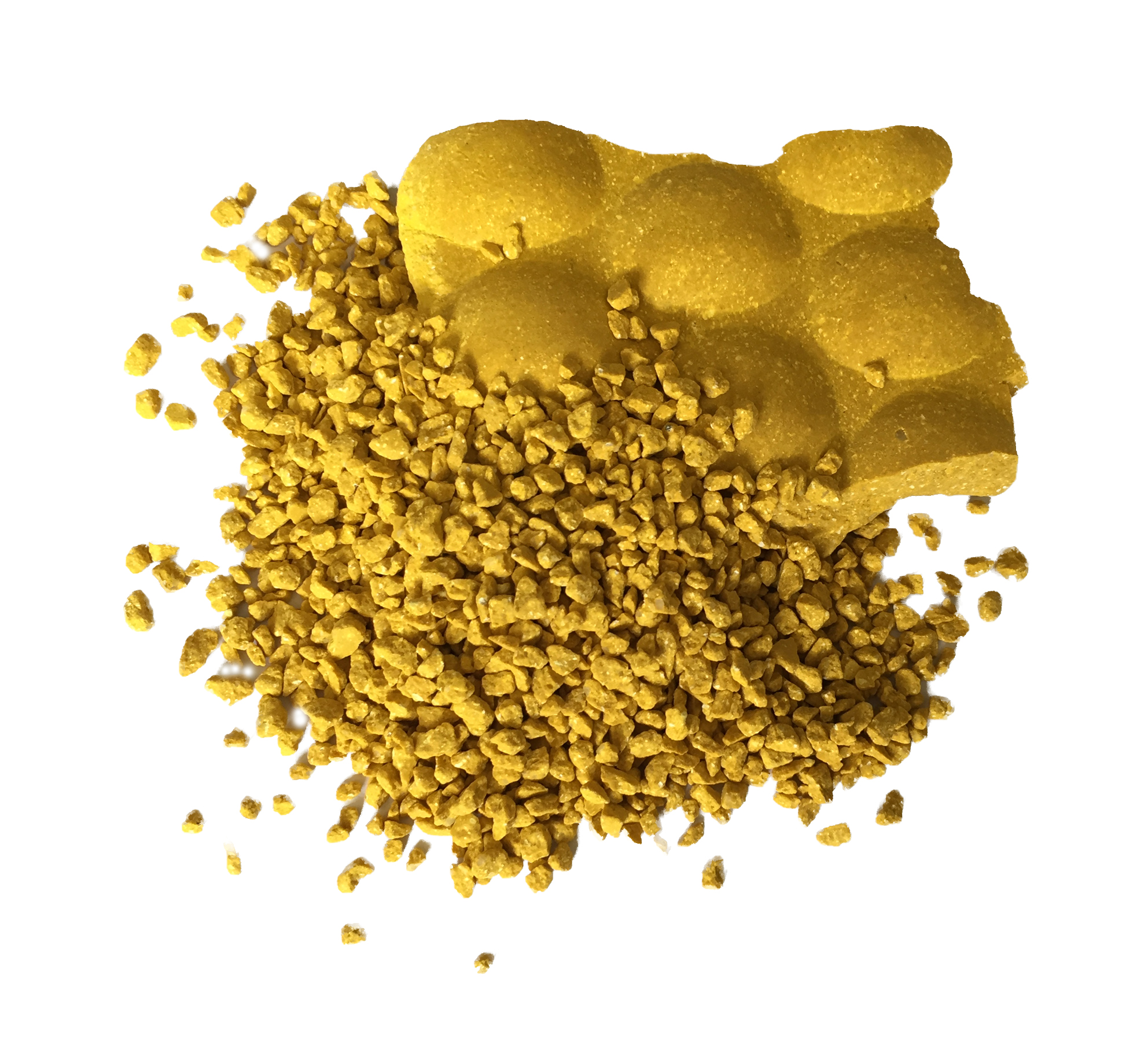

- A granulation-screening unit converting the flakes into granules of the required calibrated range.

- And for some plants and in particular for the production of compacted fertilizers, a finishing unit with polishing and coating of granules for improving appearance (round shape), anticaking and reducing amount of residual fines with easier storage.

- Transferring of granules into storage boxes.

- Packing and pelletizing of finished products.

Usual complete compaction-granulation plant for NPK fertilizers

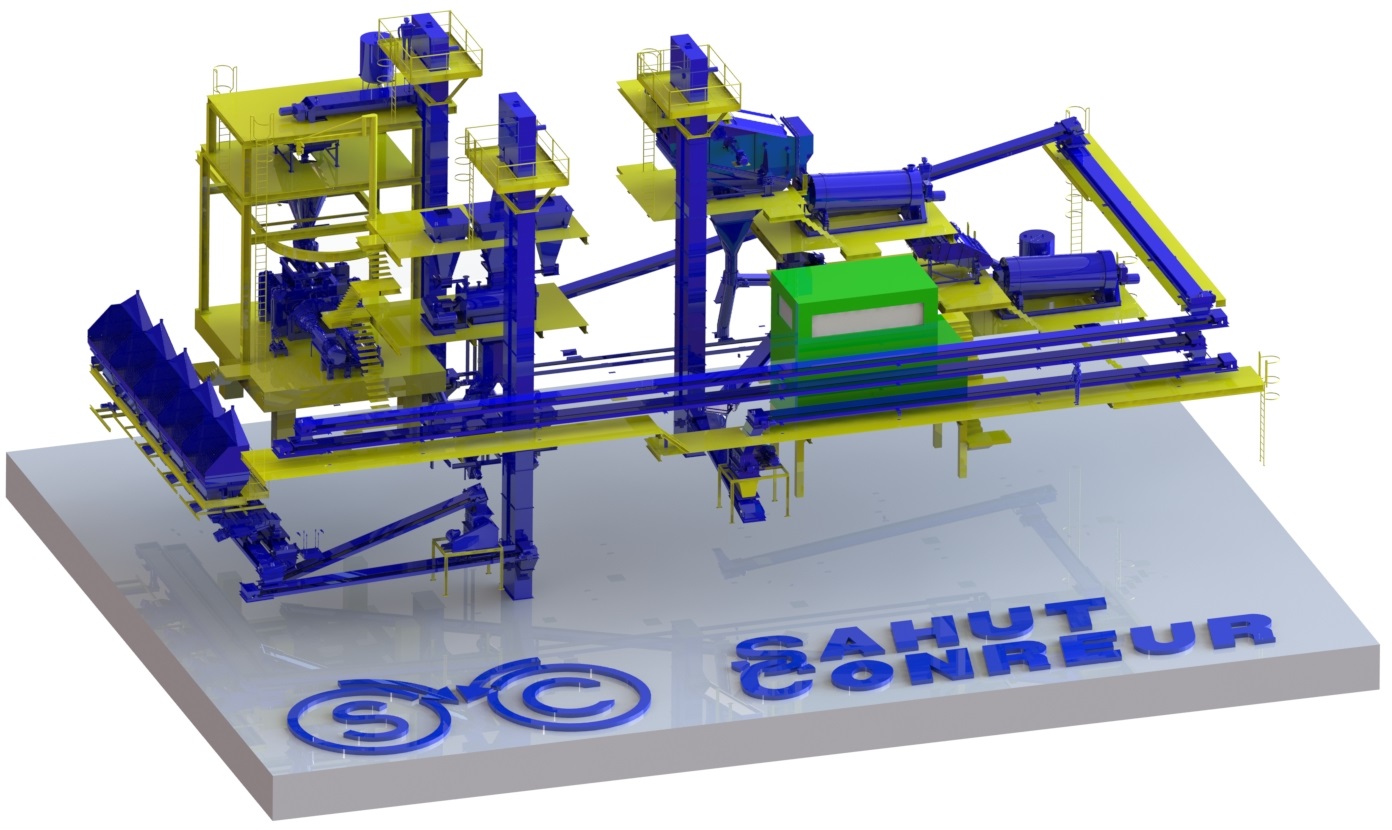

28 Tph NPK fertilizers compaction-granulation plant

Main advantages of NPK compaction-granulation

A TECHNICAL SOLUTION

- No segregation problems.

- Less tendency for caking.

- Quick change during the production : 30 minutes.

- 2 T/h to 60 T/h : full automated plant.

A COMMERCIAL SOLUTION

- Wide spectrum of fertilizer formulas.

- Production of small quantity per formula : great flexibility.

AN ENVIRONMENTAL SOLUTION

- No pollution problem : no gas and liquid effluents.

AN ECONOMICAL SOLUTION

- Dry process: no energy for drying.

- Few corrosion problems : low maintenance cost.

- Low investment cost : neither dryer nor cooler equipment.

- High adaptability to the local market for the raw materials.

A COMPLETE RANGE OF EQUIPMENT

For this type of fertilizers plant,SAHUT-CONREUR

is able to design and manufacture/supply the following equipment:

Mixer

Granulators

Screens

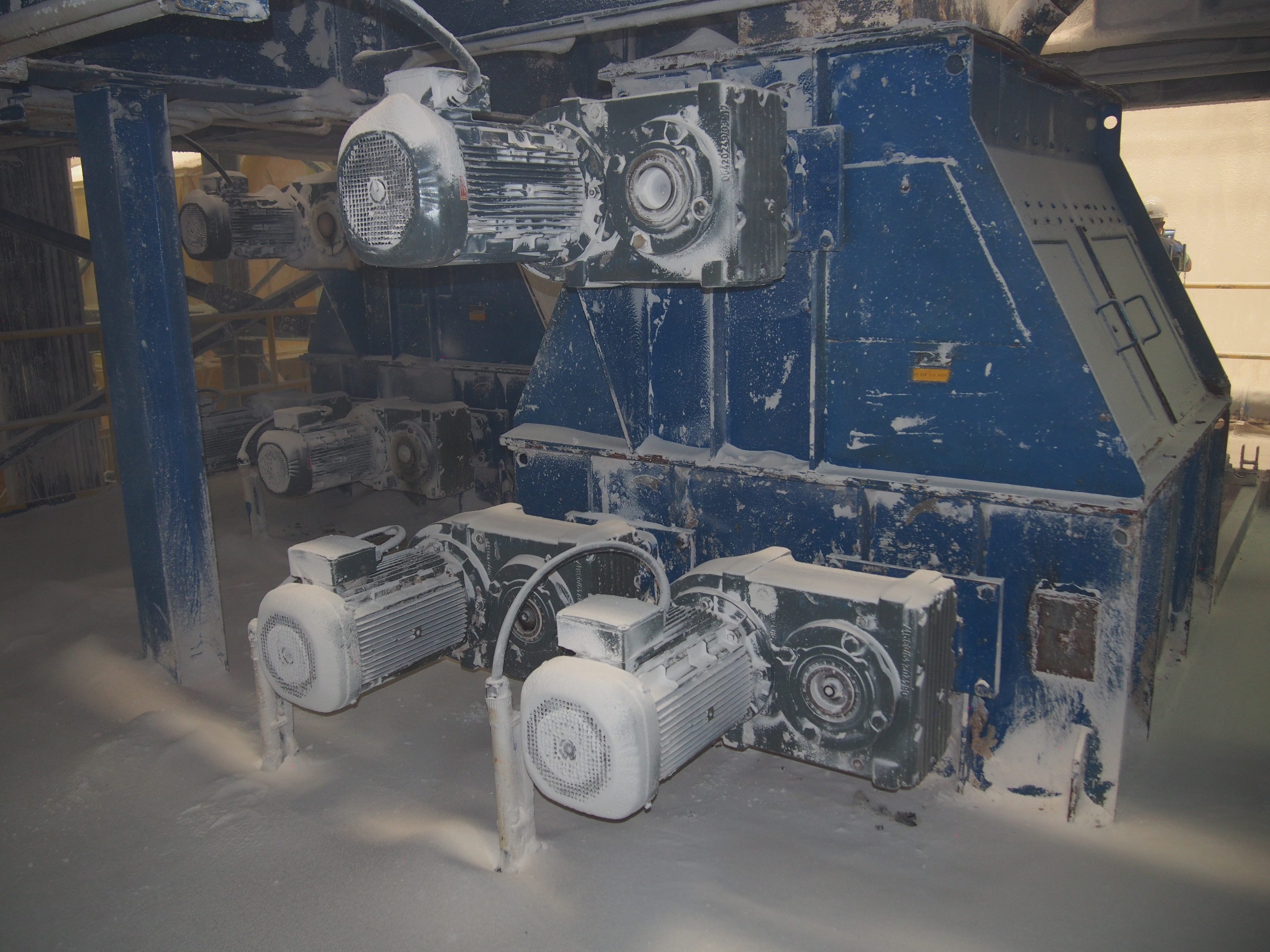

Compactor

Twin screw mixer

Dedusting system

Polishing drum

Flake-breaker

Coating drum

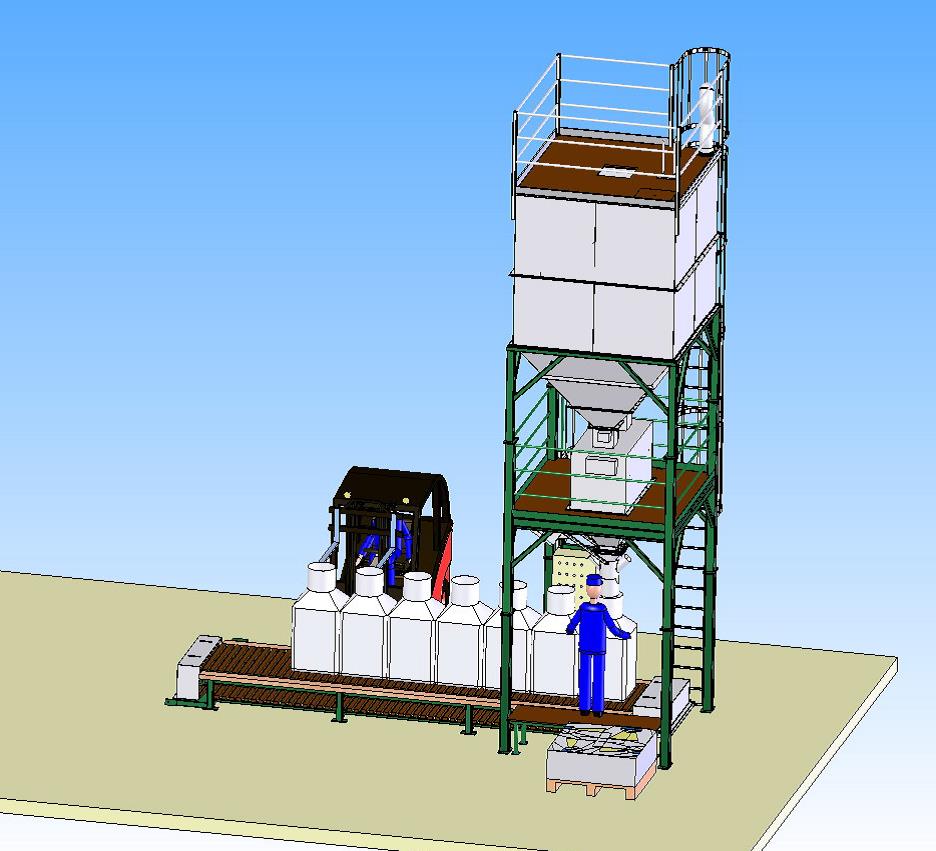

Packing unit

MCC

Control-drive system