Services

SAHUT-CONREUR

can offer you the following range of services:

Test runs and feasibility studies at the pilot plant

TheSAHUT-CONREUR

’s pilot plant is at customer’s disposal to carry out a tests session with raw material in order to determine and fix the best possible products quality that can be reached in its final process. Fitted with a full range of lab and industrial equipment necessary to determine the key process parameters, all feasibility testing on briquetting, compaction - granulation or grinding of products can be carried out in this test lab in active collaboration with customers. Read more about our pilot plant.

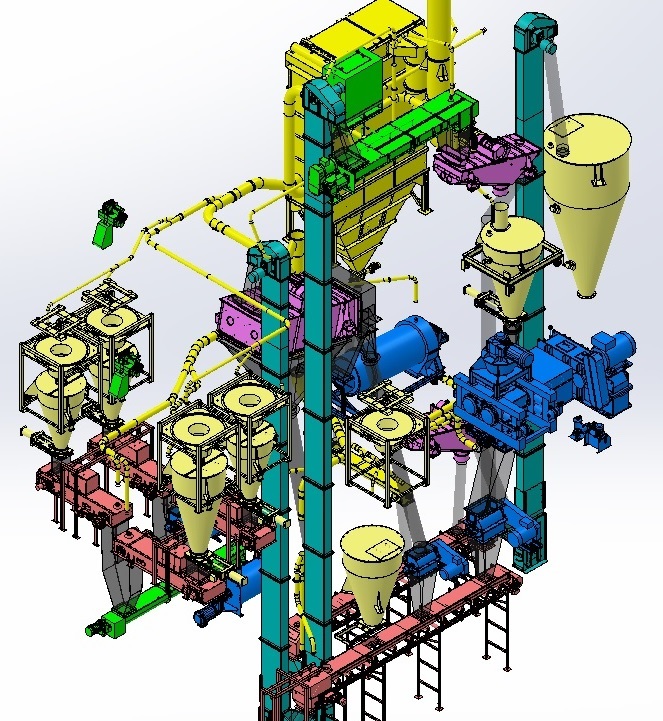

Basic and detail engineering of briquetting and compaction-granulation units

The engineering department is in charge of drawing-up the preliminary project drawings and then ensures the basic and detail engineering of the briquetting and compaction-granulation units. This department provides customers with important services ensuring the integration of equipment into the process in each application and ensuring that the material meets the required specifications. Read more about our engineering department.

Design and manufacture of the key-equipment of briquetting and compaction-granulation units

Equipped with 3D CAD Softwares, the engineering department and its skilled technicians and engineers realize the design of the key-equipment (crusher, dryer, mixer, press, granulator, polishing-coating drums, screen, packing, handling and storage equipment) integrated in the briquetting and compaction-granulation units. Read more about our engineering department.

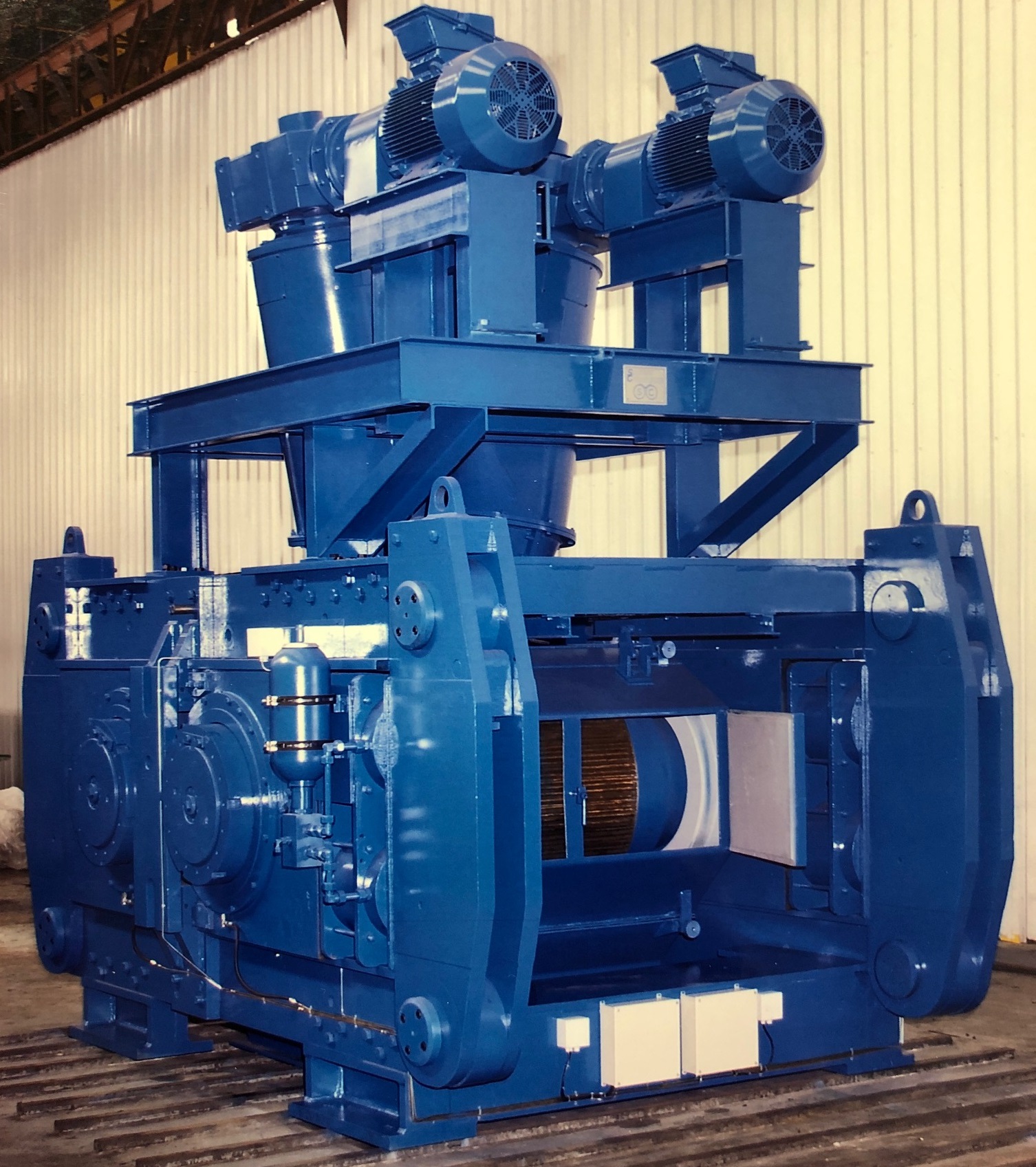

Design and manufacture of HPGR roller presses

Equipped with 3D CAD Softwares, the engineering department and its skilled technicians and engineers realize the design of the HPGR roller destined to the grinding plants. Read more about our engineering department.

Technical assistance for mounting and commissioning

One of the advantages of working withSAHUT-CONREUR

is that we are not only designing and manufacturing our own equipment, but also providing a commissioning services and ongoing support throughout the life of the product.SAHUT-CONREUR

has a group of skilled personnel who can go to the site to assist in the commissioning and maintenance. We understand that downtime could be costly, and our field technical staff is well-qualified to ensure the smooth operation of your business as soon as possible.

Training of operators

After the erection and the commissioning completed,SAHUT-CONREUR

ensures the training of the operators by instructing them about all they need to know about operation, lubricating, safety and mechanical/electrical maintenance purposes on our equipment. Our instructors have rich and long experience regarding the equipment life and give precious advises to the operators so that they are able to ensure by themselves the continuous running of the equipment.

Supply of spare parts

Although theSAHUT-CONREUR

equipment are heavy-duty designed to operate in difficult conditions with continuous running, it is therefore necessary to replace wearing parts or to get safety spare-parts at customer warehouse disposal in order to be able to maintain the equipment in place very quickly and reduce the production downtime.SAHUT-CONREUR

ensures the supply of spare parts, without time limit for the parts manufactured by itself.SAHUT-CONREUR

is also able to supply spare-parts for equipment delivered by others.

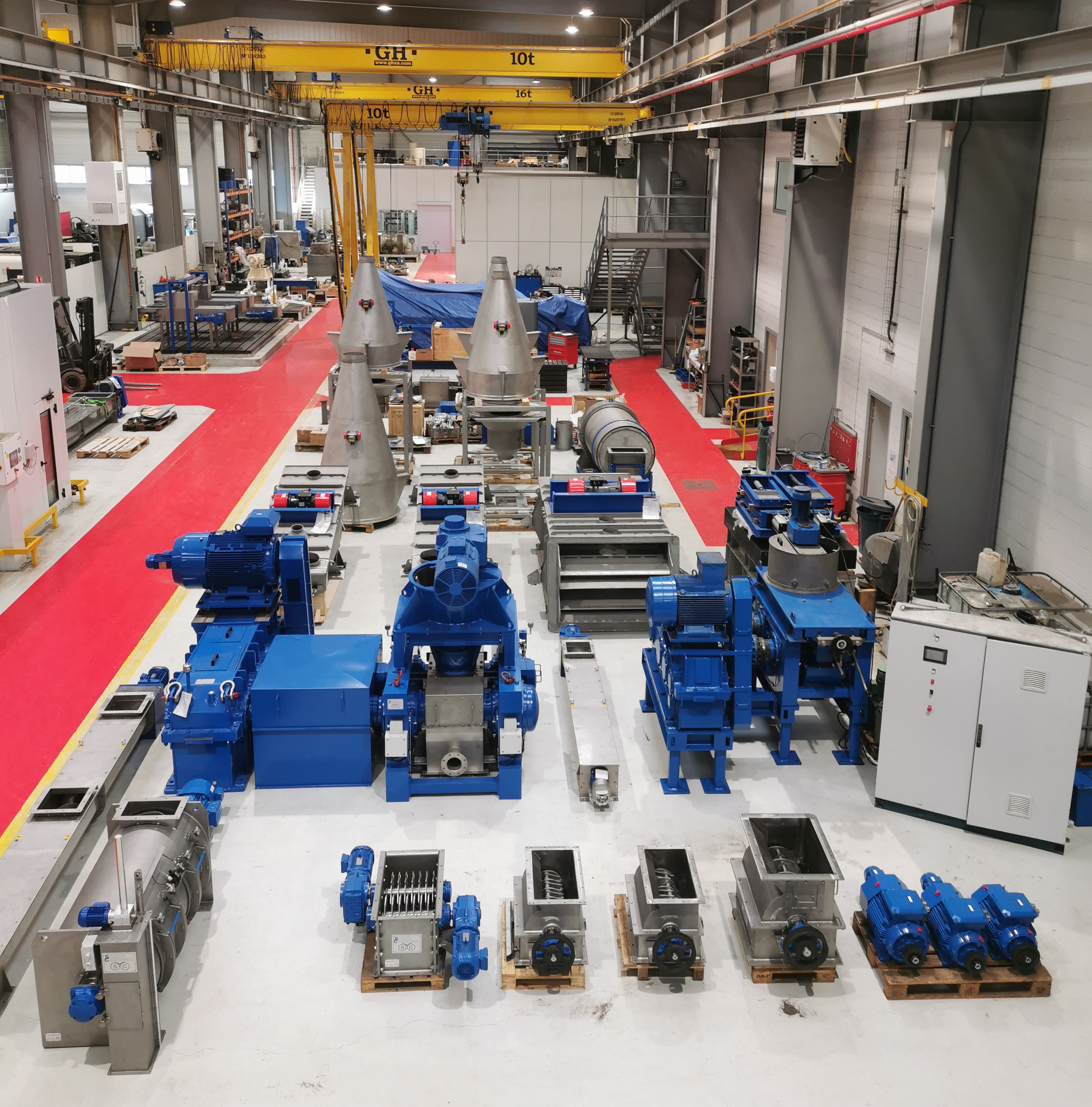

Custom-made production at the production plant

TheSAHUT-CONREUR

’s production plant is available for delivering a toll production to the customer. Equipped with all equipment enabling a continuous production of batches of briquettes or granules, the tool production plant gives many opportunities to our customers to test their final products before investment. Read more about our toll production plant.

Rental of industrial briquetting press and compaction equipment for site testing

SAHUT-CONREUR

proposes a set of rental equipment for clients who wish to test a briquetting or compaction-granulation process on their own site in France or worldwide and at the same time to sample a potential market. The admissible production capacity of this rental equipment ranges from 50 kg/h to 5 t/h. Rental equipment can include the following individual equipment : single or multi-product dosing unit, mixers of different technologies, presses/compactors with different feeding systems (feed hopper with flaps, gravity-feeder, force-feeder), crushing/granulation equipment, polishing/coating drum, handling equipment, MCC/Control-drive cabinets.

Rental of complete units for briquetting and compaction-granulation for testing and site productions

SAHUT-CONREUR

proposes the following turn-key briquetting and compaction-granulation units available for rent:- Turnkey briquetting unit for a capacity of 100kg/h.

- Turnkey briquetting unit for a capacity of 1t/h.

- Turnkey briquetting unit for a capacity of 50kg/h.

- Turnkey briquetting unit for a capacity of 500kg/h.

Adaptation of SC technology to equipment manufactured by other manufacturers

Customers may not be satisfied with the operation of equipment/units purchased from our competitors.SAHUT-CONREUR

can delegate a team of specialists who, thanks to their qualification and experience, are qualified to audit and propose modifications to improve installations/equipment that do not work or do not meet the requirements of the end- users. These improvements are aimed to optimize operation, production costs or reduce maintenance. This type of service has already been successfully performed several times and these customers have become ours today and we continue the collaboration together.

Audit and modernization of existing plants and equipment

There are many reasons why manufacturers may need to upgrade existing plants: environmental regulations, obsolete equipment, or expansion of the enterprise, etc. Regardless of the reason, the companySAHUT-CONREUR

can cooperate with customers in the process of changes and improvements to their enterprises.SAHUT-CONREUR

process engineers could be named as real specialists who are able to offer the best equipment for existing enterprises. They will come to your production site to consider the needs associated with the field of application and understand the conditions of your enterprise. Then, they can also evaluate the optimal technological solution to improve the efficiency or productivity of the system.